What Is Mining Mill Used In Mineral Processing

Mineral processing milling

2015年8月8日 — Milling, sometimes also known as fine grinding, pulverising or comminution, is the process of reducing materials to a powder of fine or very fine size It is distinct from crushing or granulation, which involves size reduction to a rock, pebble or grain size2023年10月10日 — A SAG mill, or semiautogenous grinding mill, is a type of machine used in mining and mineral processing operations It uses the crushing and grinding action of rocks to reduce materials such as copper Understanding the SAG Mill in Copper Ore Generally, mineral processing begins when an ore is delivered from a mine, to a processing facility At this point, the ore is called runofmine material because there has been no Introduction to Mineral Processing or Beneficiation Sepro Mineral Mineral processing Concentration, Separation, Flotation: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill In largescale operations this is Mineral processing Concentration, Separation,

Review on advances in mineral processing technologies

2022年4月1日 — The extraction of critical metals in a circular mining system involves four main steps: mineral processing, metal extraction, metal recovery, and residue Mining and mineral processing generates large volumes of waste, including waste rock, mill tailings, and mineral refinery wastes The oxidation of sulfide minerals in the materials Mineral Processing an overview ScienceDirect Topics2023年6月7日 — The purpose of mineral processing is to treat the nonstandard, unsorted, and lowgrade complex paragenic minerals into wellsorted concentrates that meet the Mineral Processing SpringerLink2023年5月3日 — Mineral processing plant is a plant in which mineral processing is implemented to obtain concentrate products that are suitable for metallurgy or other Mineral Processing Plant SpringerLink

UNDErsTaNDINg MINE TO MILL 911 Metallurgist

2024年9月20日 — Mine to Mill, which links aspects of mining and mineral processing in order to optimise the combined mining and processing stages, has been under development 131 In situ leach recovery (The merging of mining and processing) In situ recovery (ISR), also called in situ leaching (ISL) or solution mining, is a mining process used to recover minerals such as copper and uranium Physical Processing: Innovations in Mineral 2022年5月16日 — Mineral processing and exploration add significant carbon emissions to the environment There is a growing emphasis on ethical mining to reduce the environmental and material imprint of the entire Using Artificial Intelligence for Mineral 6 天之前 — As a result, mineral processing is designed to yield the maximum amount of mineral concentrate possible before products hit the market If the case cannot be made for profitable yields of valuable minerals, then a Essential Guide to Mineral Processing

Mining and Mineral Processing Carmeuse Systems

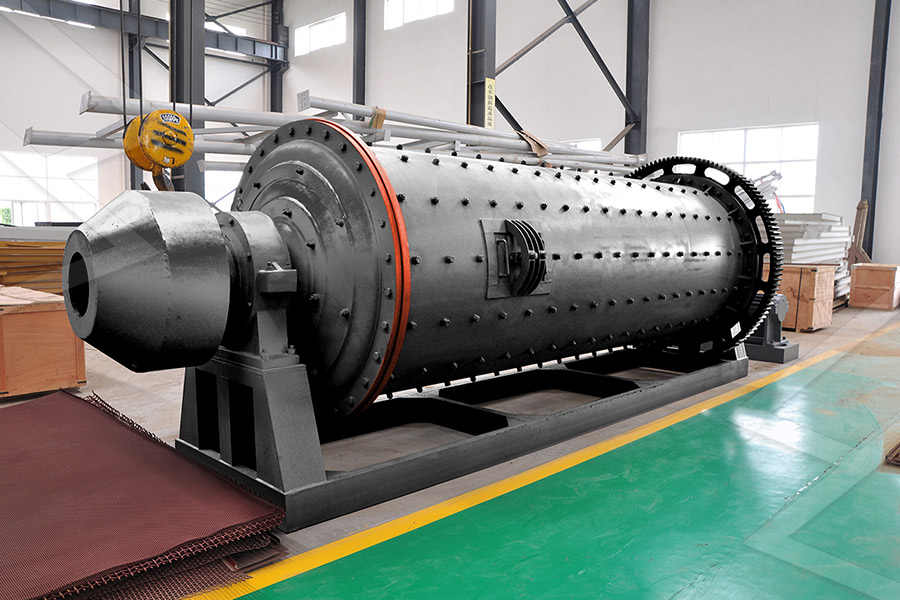

Lime is used in mining and mineral processing for its strong alkalizing effect: we have partnered with to integrate ’s wellknown VERTIMILL ® vertical ball mill with our patented lime feed design into a vertical ball mill slaker system that is ideal for mineral processing operations2024年3月7日 — In this process, the material to be ground is fed into the mill in dry condition, and the grinding action occurs through mechanical forces exerted by the movement of the balls within the mill It is commonly used in various industries such as mineral processing, ceramics, metallurgy, and pharmaceuticals to produce fine powders or particles from Application of Dry Ball Milling in Mineral Processing13 RunOfMine Material and Minerals Generally, mineral processing begins when an ore is delivered from a mine, to a processing facility (SAG) milling has seen increased use in recent years, especially in large mineral processing operations These mills typically have a large diameter relative to their length, typically in the ratio or 2 Introduction to Mineral Processing or Beneficiation Sepro Mineral 2019年11月1日 — In grinding mills, fresh and reactive mineral surfaces are continuously generated making it the most frequently used alkali in mineral processing bornite, and gold in seawater In The First International Symposium on Water in Mineral Processing Society for Mining, Metallurgy, and Exploration, Seattle, USA Google Scholar du Plessis Lime use and functionality in sulphide mineral flotation: A

Mining Definition, History, Examples, Types, Effects, Facts

2024年9月21日 — mining, process of extracting useful minerals from the surface of the Earth, including the seasA mineral, with a few exceptions, is an inorganic substance occurring in nature that has a definite chemical composition and distinctive physical properties or molecular structure (One organic substance, coal, is often discussed as a mineral as 2005年12月2日 — Minerals recovery from the earth's crust and the subsequent processing of economic mineral deposits, ie, ores, constitutes a wide variety of steps Taken together these represent one of the world (PDF) Minerals Recovery and Processing ResearchGate6 天之前 — Mining magnetic separator is common equipment in mineral processing And magnetic separation is the main method of iron ore dressing What minerals are required for magnetic separation? Common Types of Mining Magnetic Separators Mineral 2023年2月17日 — The analysis in this article was enabled by MineSpans, which is a proprietary McKinsey solution that provides mining operators and investors with robust cost curves, commodity supply and demand Copperprocessing technologies: Growing

(PDF) Comminution a Heart of Mineral

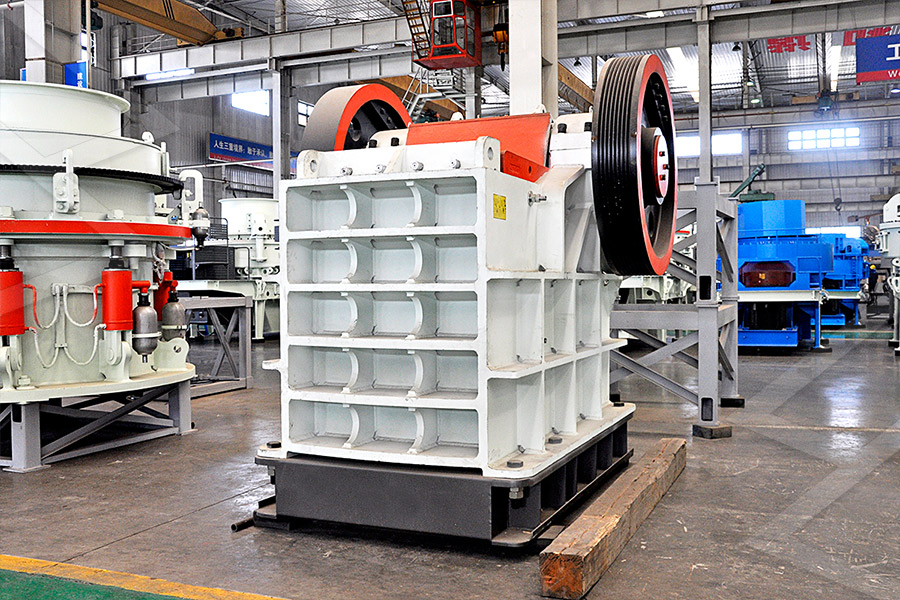

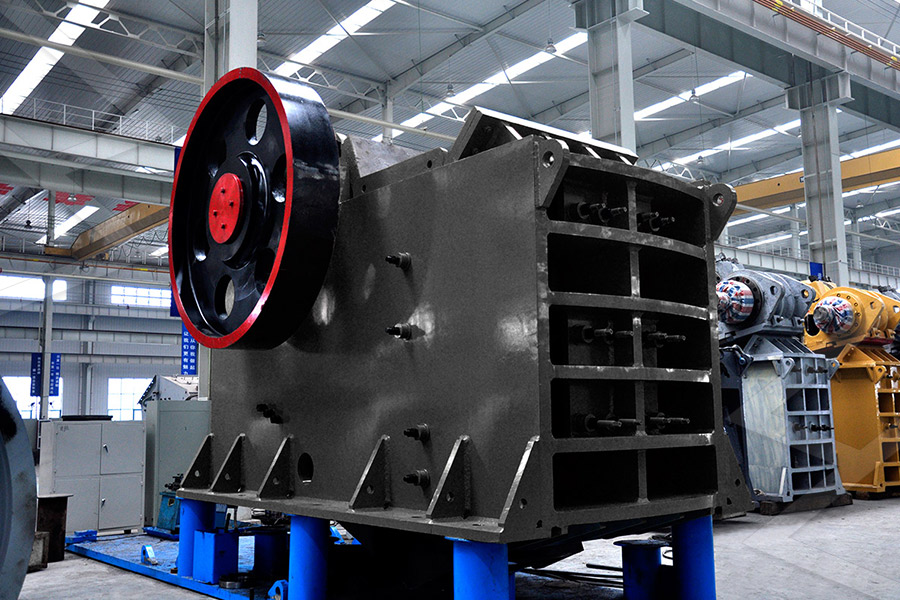

2021年7月6日 — The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market Further, even Mine to Mill strategy was adopted without maintaining the target 2015年12月26日 — In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant Crushing in Mineral Processing 911MetallurgistWhen iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingThe six main steps of iron ore processing MultotecThe process of comminution is the crushing and grinding of a material / ore to reduce it to smaller or finer particles The comminution process reduces particle sizes by breaking, crushing, or grinding of ore, rock, coal, or other materials The process is most often used in the field of mining and / or mineral processing, where mineral ore is broken down into Comminution Multotec

Automation and Robotics in Mining and Mineral Processing

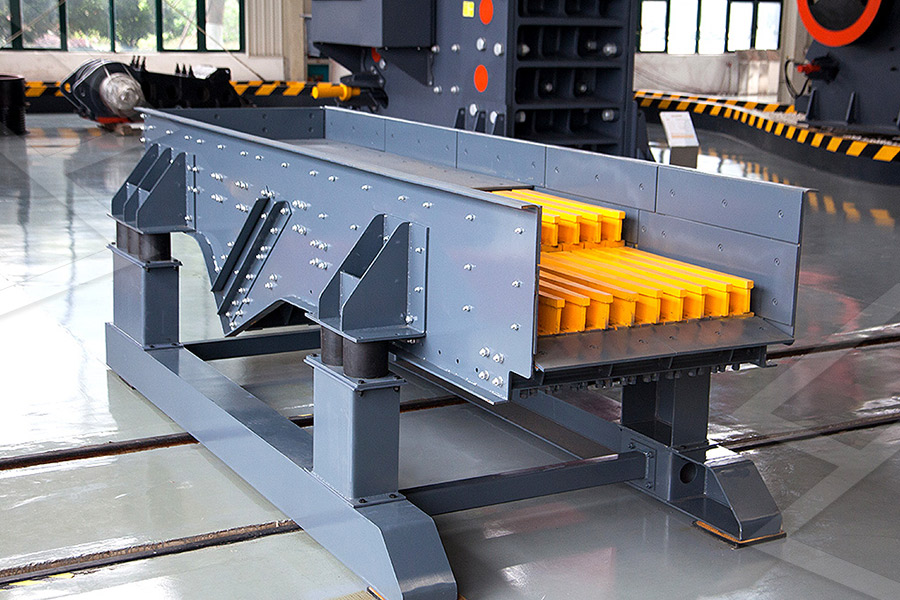

2023年6月17日 — Integrated planning for mining and mineral processing is looked for, and more use of process data knowledge from mine to product is needed Indirect instruments are mostly used in mill or hydrocyclone operation monitoring These measurements are based, for example, on acoustic measurements, visionbased monitoring, mill liner The following process description is based upon a ball mill used in the hard rock mining industry for liberating minerals from ore, but the operating principle for ball mills used in other industries is the same Crushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constantBall Mill (Ball Mills Explained) saVRee saVRee2024年8月20日 — For example, Hatch offers two solutions — Mine to Mill and Grade Engineering — that aim to increase the overall efficiency of mineral processing operations, inclusive of flotation Richter explained: “Mine to Mill is a consolidated approach focusing on optimizing mining operations across the value chain with a specific focus on mining Flotation: The Past, Present and Future of Mineral Processing?2016年5月26日 — Spiral Classifier In mineral processing, the Akins AKA spiral or screw Classifier has been successfully used for so many years that most mill operators are familiar with its principle and operationTypes of Classifiers in Mineral Processing 911Metallurgist

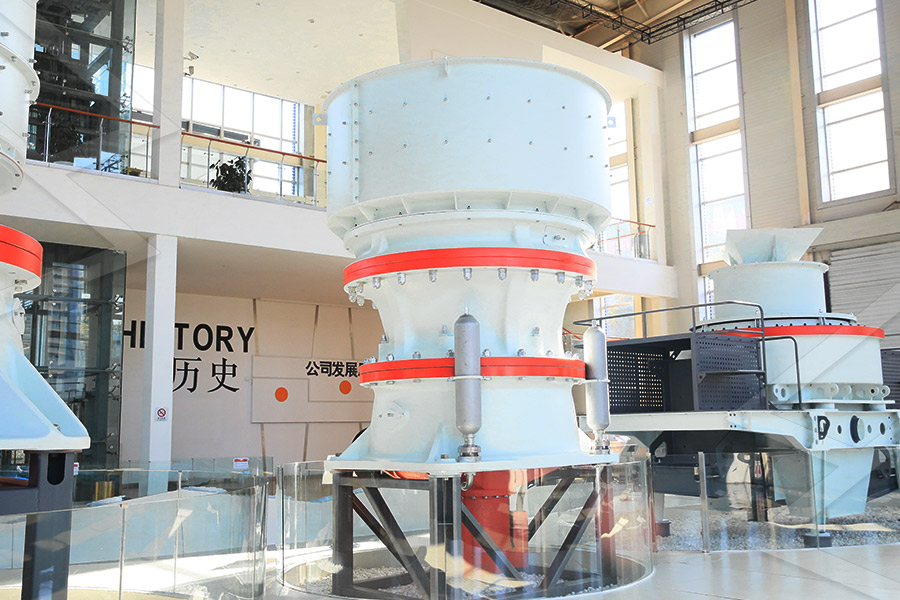

Energy Use of Fine Grinding in Mineral Processing

2013年12月18日 — Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred 2018年11月19日 — The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market Generally, the ability of treating crude material from excavation into mineral (PDF) Comminution in mineral processing2024年9月22日 — Understanding the operation of grinding mills in the mining and mineral processing industry Grinding mills are crucial equipment in the mining and mineral processing industry, used primarily for the reduction of ore and mineral particles The proper functioning of grinding mills is vital for the efficiency of the overall processing plantUnderstanding the operation of grinding mills in the mining and mineral 2022年4月1日 — Mineral processing operations generally follow a set of specific steps to separate ores into products rich in valuable minerals (concentrate) and waste streams The breakdown of the mineral processing steps within the mining chain is illustrated in Fig 3 Run of mine ore undergoes an initial process of crushing, milling and classification to Review on advances in mineral processing technologies

Grinding Mills — Types, Working Principle Applications

2018年8月17日 — SemiAutogenous Mills/ SAG Mills (primary grinding mill) — these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore particles that result in Mineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in situ position These materials can be used directly or by simple or complex processing and even by applying extractive metallurgy like hydrometallurgical or pyrometallurgical methodsMineral Processing an overview ScienceDirect TopicsAll processing activities can lose some of the desired mineral resources, which may occur at any processing stage, with some mining projects losing more than others In turn, to measure the amount of recovered mineral, a plant has a recovery percentage, which is the mass of product recovered for final disposal, divided by the mass of the raw Mineral Processing Plants Multotec3 天之前 — The actual mining of gold is just one step of the gold mining process Learn how gold is mined and the five stages of a large scale gold mining project as accurately as possible, the size of the mineral deposit, as well as how to extract and process the ore efficiently, safely and responsibly How Gold Is Mined Gold Mining Process World Gold Council

Trends and Best Practice Mineral Processing

2023年10月27日 — Advances in comminution, the process of reducing solid material into smaller particles, have been a focal point in the mining and mineral processing industry, with significant developments reflecting both current trends and best practices One prominent trend is the growing emphasis on sustainability Comminution is an energyintensive After ore containing an economicallyrecoverable commodity is mined from the earth, that commodity is extracted in a processing plant or mill After the commodity of value is extracted from the ore material, the resultant waste stream is termed “tailings” Typically, mill tailings range from sand to siltclay in particle sizeWhat are Tailings Society for Mining, Metallurgy2 天之前 — Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products Copper Mining and Processing: Processing 2022年10月4日 — A notable fact is that the energy efficiency of conventional milling is only about 1%, as mentioned in Sect 1 An earlier experimental study indicated that about 80–90% of the energy input of a ball mill was used in heating the material (Schellinger 1951, 1952), and a recent study showed that over 75% of the electrical energy was used to Reduction of Fragment Size from Mining to Mineral Processing

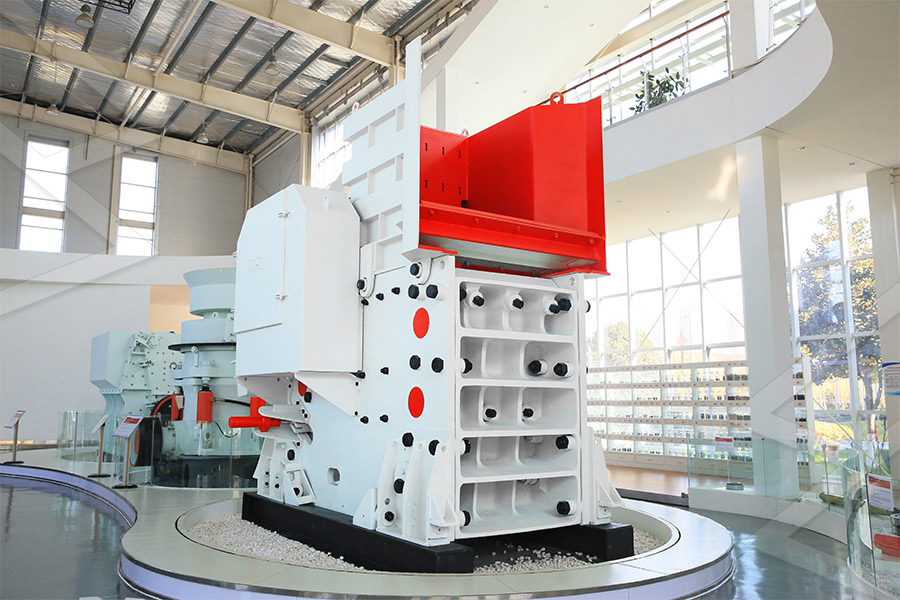

Mining Crushers, Breakers Grinding Mills for the Mining

4 天之前 — Finding suppliers of mining crushers, breakers and grinding mills Crushers, breakers and grinding mills come in several different types Mining Technology has listed some of the leading suppliers of processing equipment in the mining drills and breakers market, based on its intel, insights and decades of experience in the sector The list 2016年1月17日 — The use of hammer mills is in the field of softer minerals, such as gypsum, barytes and limestone, and particularly where the presence of clay would most definitely exclude the use of crushing machines in which fracture of the mineral is effected by pressure In this latter field in particular, the hammer mill is also used as a primary crusherCrushing Mineral Processing 911Metallurgist2022年2月23日 — Mineral processing is a field that contends with procedures and technologies used for separating valuable minerals from gangue or waste rock It is a process that converts the extracted ore through mining activity into a more concentrated material, which serves as an input for the extractive metallurgyAdvanced Analytics for Mineral Processing SpringerLink2023年6月1日 — The yield in mineral processing is the quantity of material that is recovered from an ore after it has been processed what is the difference between tube grinder and ball mill Aug 25, 2023 What is the yield in mineral processing? LinkedIn

Lecture 11: Material balance in mineral processing

Lecture 11: Material balance in mineral processingSpirals in Australian mineral processing Mining is an important industry for Australia and contributes significantly to the country's economy Minerals mined in Australia include iron ore, coal, gold, copper, nickel and zinc Spiral concentrators are used in mineral processing for separating mineralsSpirals in Australia mineral processing Multotec2016年3月8日 — The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Flotation Cells, and Selective Mineral Jigs as well as other standard milling Mineral Processing Flowsheets 911Metallurgist2019年8月16日 — Mining, mineral processing and metal extraction are undergoing a profound transformation as a result of two revolutions in the making—one, advances in digital technologies and the other, availability of electricity from renewable energy sources at affordable prices The demand for new metals and materials has also arisen Future of Mining, Mineral Processing and Metal Extraction

Physical Processing: Innovations in Mineral

131 In situ leach recovery (The merging of mining and processing) In situ recovery (ISR), also called in situ leaching (ISL) or solution mining, is a mining process used to recover minerals such as copper and uranium 2022年5月16日 — Mineral processing and exploration add significant carbon emissions to the environment There is a growing emphasis on ethical mining to reduce the environmental and material imprint of the entire Using Artificial Intelligence for Mineral 6 天之前 — As a result, mineral processing is designed to yield the maximum amount of mineral concentrate possible before products hit the market If the case cannot be made for profitable yields of valuable minerals, then a Essential Guide to Mineral ProcessingLime is used in mining and mineral processing for its strong alkalizing effect: we have partnered with to integrate ’s wellknown VERTIMILL ® vertical ball mill with our patented lime feed design into a vertical ball mill slaker system that is ideal for mineral processing operationsMining and Mineral Processing Carmeuse Systems

Application of Dry Ball Milling in Mineral Processing

2024年3月7日 — In this process, the material to be ground is fed into the mill in dry condition, and the grinding action occurs through mechanical forces exerted by the movement of the balls within the mill It is commonly used in various industries such as mineral processing, ceramics, metallurgy, and pharmaceuticals to produce fine powders or particles from 13 RunOfMine Material and Minerals Generally, mineral processing begins when an ore is delivered from a mine, to a processing facility (SAG) milling has seen increased use in recent years, especially in large mineral processing operations These mills typically have a large diameter relative to their length, typically in the ratio or 2 Introduction to Mineral Processing or Beneficiation Sepro Mineral 2019年11月1日 — In grinding mills, fresh and reactive mineral surfaces are continuously generated making it the most frequently used alkali in mineral processing bornite, and gold in seawater In The First International Symposium on Water in Mineral Processing Society for Mining, Metallurgy, and Exploration, Seattle, USA Google Scholar du Plessis Lime use and functionality in sulphide mineral flotation: A 2024年9月21日 — mining, process of extracting useful minerals from the surface of the Earth, including the seasA mineral, with a few exceptions, is an inorganic substance occurring in nature that has a definite chemical composition and distinctive physical properties or molecular structure (One organic substance, coal, is often discussed as a mineral as Mining Definition, History, Examples, Types, Effects, Facts

(PDF) Minerals Recovery and Processing ResearchGate

2005年12月2日 — Minerals recovery from the earth's crust and the subsequent processing of economic mineral deposits, ie, ores, constitutes a wide variety of steps Taken together these represent one of the world