Screening Equipment For Sizing Crushed Line

.jpg)

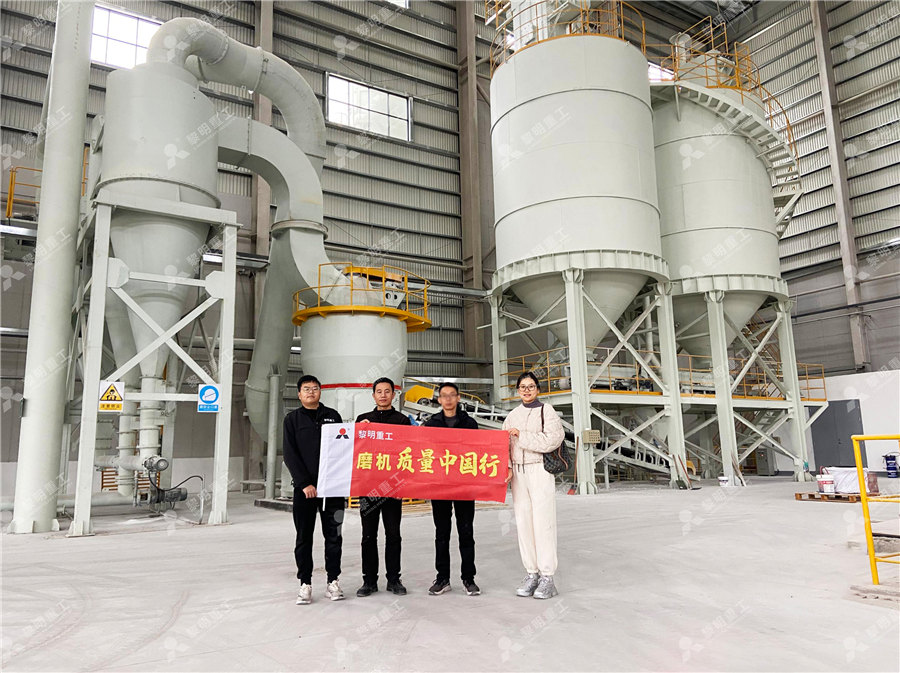

Crushing and Screening Handbook AusIMM

2021年6月24日 — complete screening solutions for scalping, closed circuit screening, fi nal sizing and dewatering Single inclination, double, triple and horizontal models Sand and gravel washing – to produce special quality rock materials for demanding construction 2017年5月30日 — sizes, Meka screens provide screening efficiency that is high quality and dependable Our screens come in various sizes starting from 2 m² up to 16 m² and are CRUSHING SCREENING Crushing and ScreeningCrushing and Screening Handbook is a dive into the world of rock processing and aggregates production It goes through the main factors impacting the quality and costs of aggregates, introduces different Crushing and Screening Handbook MetsoScreening plays a key role in mining and mineral processing industry, where screening equipment is used in crushing and grinding circuits, for classification as well as for Mining screens screening equipment thyssenkrupp

Mobile screens, Doublescreens Mobile

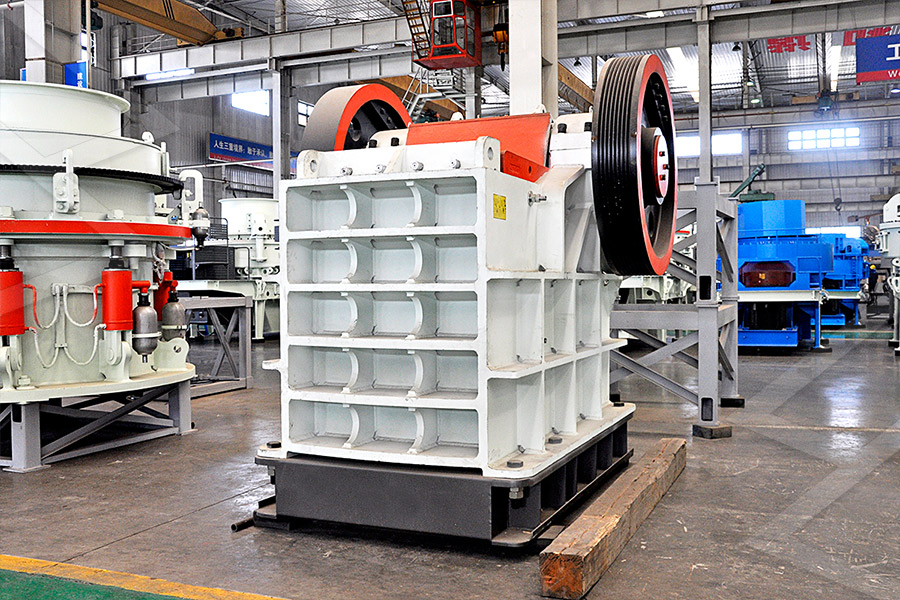

Choose from a variety of tracked mobile screeners designed for optimal performance and flexibility The Sandvik Doublescreen technology utilizes two independent, inline screenboxes This results in a marked increase 2023年2月23日 — Some common types of crushing and screening equipment include jaw crushers, cone crushers, impact crushers, and vibrating screens Each type of equipment is designed to perform a specific function in the Crushing and Screening Equipment: The 2023年6月3日 — Measurementcontrol for crushing and screening process is the measurement and control of key equipment and key process parameters to ensure the MeasurementControl for Crushing and Screening Process2023年6月2日 — Measurementcontrol for crushing and screening process is the measurement and control of key equipment and key process parameters to ensure the MeasurementControl for Crushing and Screening

.jpg)

Mineral Screening: The Complete Guide Mining

2022年12月28日 — Prescreening is the process of screening out the material with a qualifying particle size before crushing operations are carried out This process is designed to avoid overcrushing of the material and Screening: Sepro Sizing Screens Sepro Mineral Systems Sepro's line of sizing screen solutions are easily combined with other Sepro in mind, Sepro supplies durable and robust classifying screens for applications including fine aggregates, industrial minerals, coal processing and crushed stone,Screening Technologies for Recycled Glass Material screening equipment for sizing crushed liDXNne aquatroc2023年9月1日 — Commonly used mesh sizes for aggregate screens for sale from aggregate screen manufacturers include: 3/8 inch commonly used for screening sand and gravel 1/2 inch commonly used for screening crushed stone 5/8 inch commonly used for screening largersized gravel 3/4 inch commonly used for screening asphalt or concrete mixHow To Size and Select a Vibrating Screen for an Aggregate 2023年6月3日 — It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as MeasurementControl for Crushing and Screening Process

.jpg)

screening equipment for sizing crushed line stores78

Screening: Sepro Sizing Screens Sepro Mineral Systems Sepro's line of sizing screen solutions are easily combined with other Sepro in mind, Sepro supplies durable and robust classifying screens for applications including fine aggregates, industrial minerals, coal processing and crushed stone,screening equipment for sizing crushed line Stone 2023年3月14日 — Crushing Screening Equipment A portable stone crusher, a wheelmounted crushing machine is used for processing concrete recycling Vibrating screens play a critical role in the concrete screening process by separating aggregates of different sizes and types Mobile screening plant Crushed concrete has a variety of uses and Crushing and Screening Equipment for Concrete RecyclingYour ultimate guide to screening equipment Learn how to select and use the best screening machines for your project’s needs with this comprehensive resource In the construction industry, screening machines are used to separate and classify materials such as sand, gravel, and crushed stone This helps create different aggregate grades Screening Equipment Guide Ultimate Resource for Optimal This equipment sifts through various materials to separate crushed products based on their size With screening equipment, you can ensure the correctsized materials make it through, enhancing your overall efficiency Combining crushing and screening gives you an efficient process for obtaining the correct materials for your project Powerful Best Practices for Crushing and Screening Equipment

.jpg)

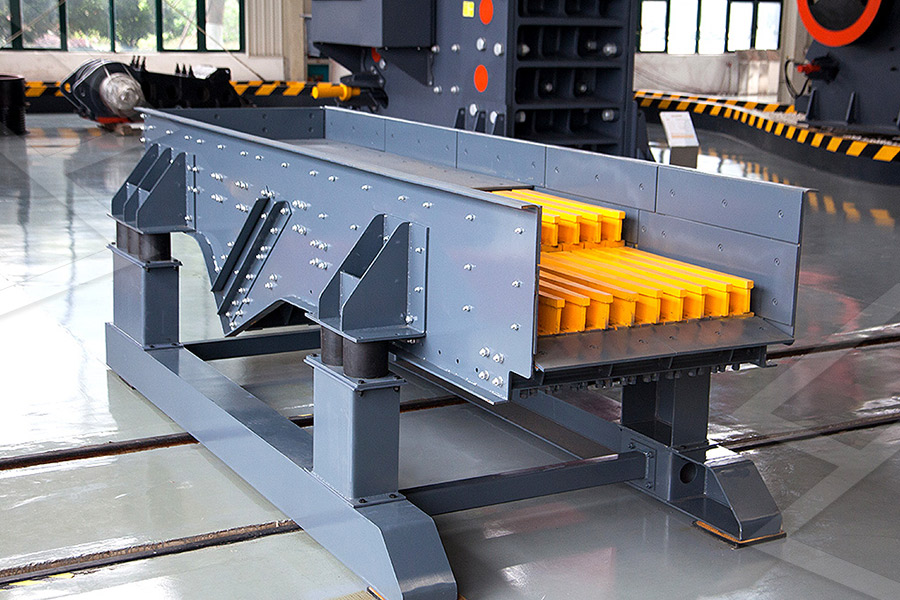

Shortcomings of Vibrating Screen and Corrective Measures:

2019年7月27日 — The screening process is usually carried out for separating two or more materials of different shapes, particle sizes and densities []The vibrating screen has wide range of application in minerals industries for the screening of minerals, mineral ores and ore slurries []It also has applications in mining industries especially in coal mining industries []The simplest form of sizing is screening, the purpose of which is to separate minerals or other materials into specific particle sizes to create various final products Screening equipment can be stationary or portable, designed for quick setup and teardown and for easy transport from site to site Screening equipment is commonly used to Screening/Sizing McLanahan2023年12月15日 — For example, let’s say we have a threelevel screen and want to produce four different size rocks If the top deck is 2″, second level 1″ and bottom level 1/2″ then four products can be made at the same How to Screen Rocks, Asphalt, Dirt and More 2024年9月4日 — New and Used Crushing Screening Machinery insights There are 10 Crushing Screening Machinery for sale in Australia from which to choose Overall 88% of Crushing Screening Machinery 546 Crushing Screening Machinery for Sale

.jpg)

Crushing and Screening Best Practices:

Use equipment such as dump trucks, loaders or excavators with appropriate capacities or bucket sizes to match the production capacity of the crushing and screening plant Grizzly feeders and scalping screens: Consider Screening plays a key role in mining and mineral processing industry, where screening equipment is used in crushing and grinding circuits, for classification as well as for dewatering and depulping The wide range of different screens from thyssenkrupp Mining Technologies is perfectly suited for these industries an offers the right screen type Mining screens screening equipment thyssenkruppThe Powerscreen H range is ideally suited to applications such as natural and crushed aggregate, coal, iron ore, recycled concrete and asphalt Conveying Equipment The Powerscreen range of mobile conveyors are designed to work in conjunction with the entire range of Powerscreen crushing and screening equipmentPowerscreen Equipment for crushing, screening more Power Screening2023年8月28日 — Aggregate Screening Equipment Sizes Aggregate vibrating screens come in various sizes The GK aggregate screens range from 5’ x 12’ to 8’ x 24’ in doubledeck and tripledeck sizes The customizable sizes allow for easier installation and make it easy to choose the perfect size for your aggregate screening load sizesAggregate Screening Equipment General Kinematics

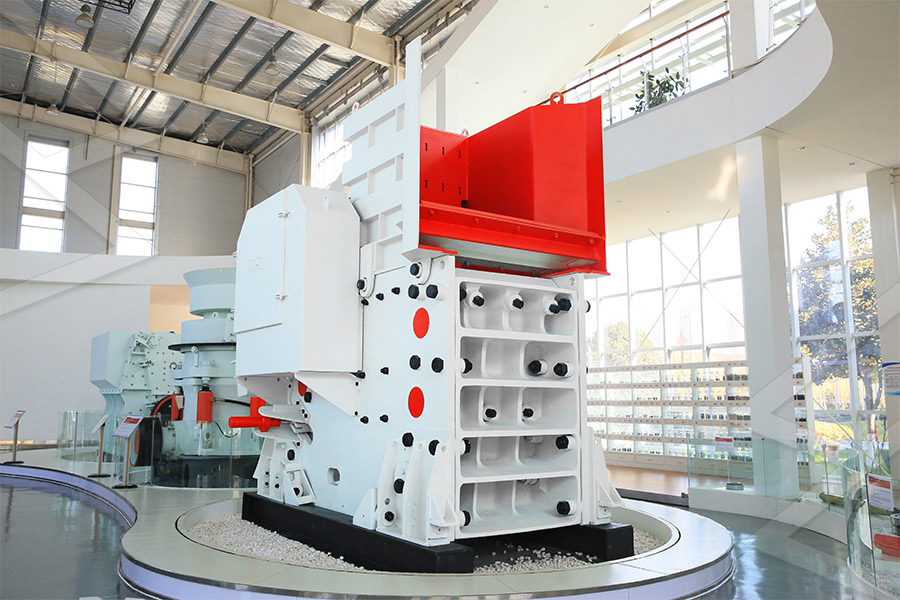

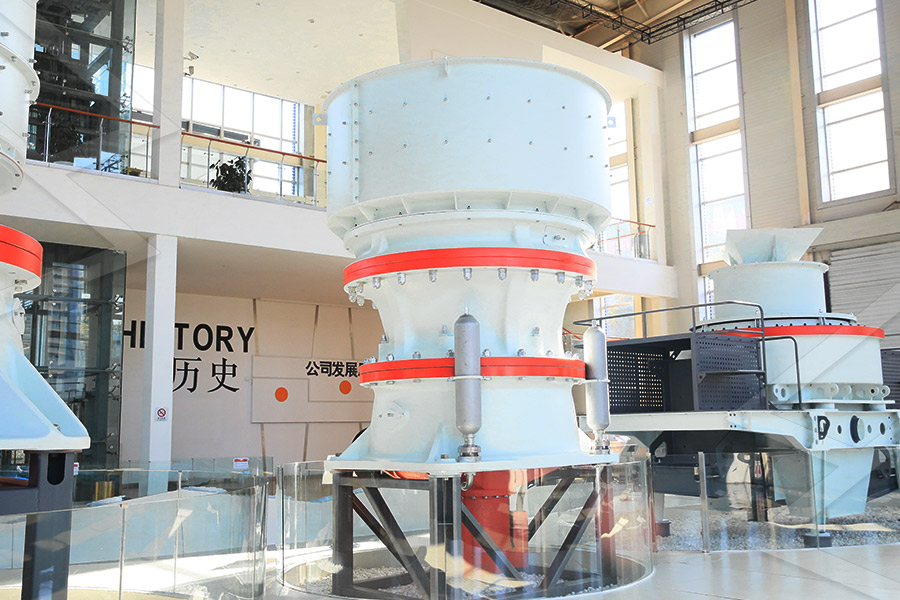

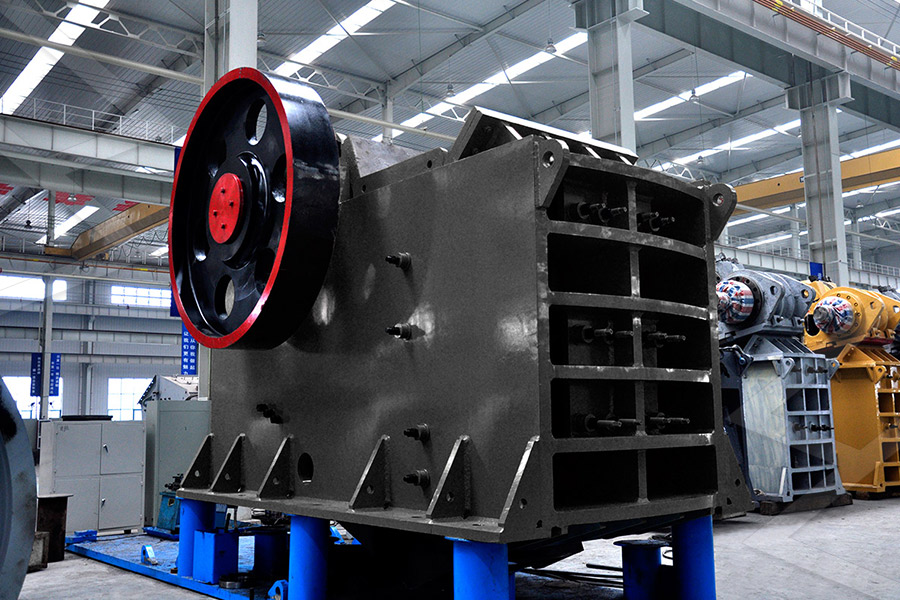

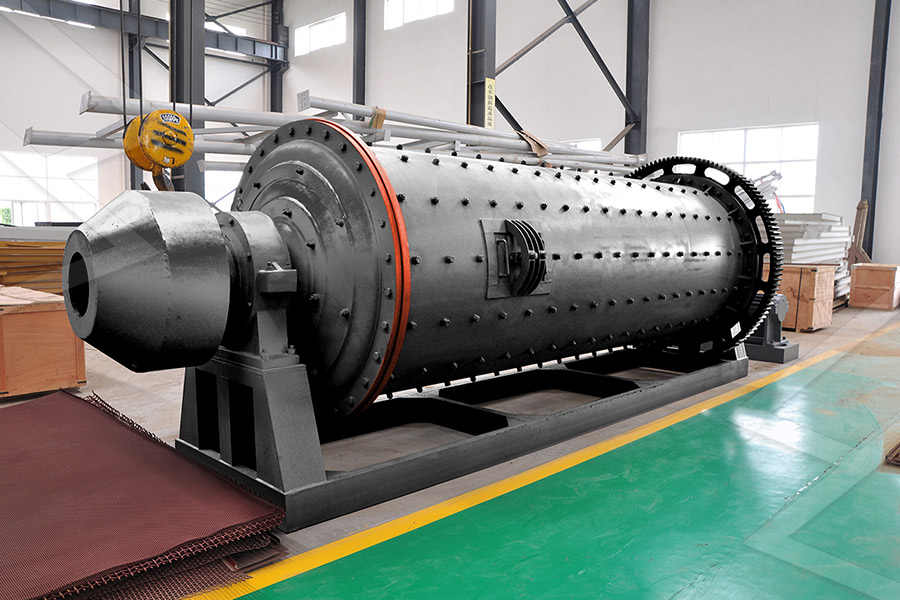

The model of crushing equipment used in the sand production line

2024年9月15日 — 4 Screening equipment: Screens are essential for separating different particle sizes in the sand production line Common screening equipment includes: * Vibrating Screen * Linear Screen These are just a few examples of the crushing equipment models used in sand production lines3 天之前 — Screening, separation, and vibration equipment in mining is essential for processing materials and extracting minerals These systems help classify and sort ore, remove unwanted material, and prepare minerals for further processing, improving efficiency and reducing costsMining Screens Mining Screening Equipment Separation McLanahan specializes in a variety of crushing solutions to reduce ROM coal to a transportable and marketable top size McLanahan crushers can take the coal producer through all stages of crushing process, from initial reduction in the primary stage to further reduction and refinement in the secondary and tertiary stages, all while minimizing the Coal McLanahan2022年2月15日 — Screening is one of the most important parts in aggregate production It takes place before and/or after the crushing stage (or stages) and produces the specifications required of the final products The purpose of screening is to separate a flow of aggregate particles into uniform sizes This is accomplished by using Vibrating ScreensHow To Size and Select a Vibrating Screen for an

43.jpg)

Rebel Crusher For Sale Rebel Concrete Crusher

The Rebel Crusher is the perfect compact mobile crushing screening machine Crush rock, limestone, brick, concrete, asphalt Made in the USA! This HIGHFREQUENCY screen filters out and sizes all of the 2 天之前 — Capacity: 301000TPH / Customizable Feed size: various sizes Application material: Stone crushing production line for crushing and screening limestone, marble, granite, basalt, cobble, andesite, river Stone Crushing Production Line JXSC Machinery3 天之前 — Screening is equally important to crushing as it enables the separation of particles of different sizes Our fleet of modern equipment includes crushers ranging from 50 to 500 tons per hour These crushers are capable of producing a wide range of highquality products, including roadstone, high quality manufactured concrete sand, base course Sustainable efficient crushing and screening services BE 2022年12月28日 — Screening refers to the process of breaking up the material into different size pairs through one or several layers of screen surface In the screening process, the sieved raw material continuously into the screening machinery, then, less than the size of the screen hole material will be through the screen hole, this part of the material is the Mineral Screening: The Complete Guide Miningpedia

.jpg)

Selecting the right crusher for your operations Quarry

2020年3月19日 — Material sizing is achieved by rotor rotational speeds and adjustments of the clearance between the blow bars and curtains The nature of HSI crushing can lead to slightly higher operating costs, the cost being incurred for greater versatility and uniform product sizing The top deck might be screening materials 50mm or less, the bottom 2013年1月1日 — Asmined coal must be crushed and sized to manageable particle sizes for either utilization, or for feed to a preparation plant This chapter reviews the methods for breaking particles, and for sorting the broken coal into sizes appropriate for further processing These include rotary breakers, roll crushers, vibrating sieves, and related Coal comminution and sizing ScienceDirectScreen sizes play a crucial role in producing different crushed stone sizes After the raw stone is crushed, screens of various sizes are used to separate the crushed stone into their respective sizes Impact of Crushed Stone Grades Crushed stone grades significantly affect the performance and suitability of the stones for various applicationsCrushed Stone Sizes Explained: Your Complete Guide5 天之前 — Screening Theory and Practice 1 Part 1 Theory of Screening The purpose of screening is to separate from a granular substance particles that are smaller than the screen opening from those that are larger This is not as simple as it sounds, and the difficulties compound as the opening becomes smaller For example, if a sample of a crushedScreening Theory and Practice 911 Metallurgist

m/sbm crushed line screening in south africamd at main

Contribute to legaojm/m development by creating an account on GitHub2022年8月7日 — ULTRACLEAN is Polydeck’s latest design upgrade to the METALDEX product line The new design increases the available screening surface by 35 sq ft on an 8 x 20ft screen deck and the VR wire design is oriented across flow to increase secondary movement, improving the cleaning effectiveness and sizing accuracyScreening: Mastering the Art of Sizing and SeparationScreening equipment is a vibrating screening mechanical equipment that uses the relative movement of the bulk material and the screen surface to make some particles pass through the screen holes and divide the sand, gravel, crushed stone and other materials into different levels according to the particle size Screening equipment is a musthave screening equipment for sizing crushed limestoneSand Screws / Fine Material Screw Washers Available from a variety of industryleading equipment manufacturers dedicated to producing the best solutions for washing and classifying, the name "sand screw" describes Aggregate Washing Equipment

.jpg)

screening equipment for sizing crushed limestone bimadit

screening equipment for sizing crushed limestone Screening at Carmeuse operations Know More Mar 05, 2018 0183 32 From the cavernous roomandpillar mine at Maysville located 250 ft below sea level, raw limestone is fed into the crushing circuits The crushed material is transported up through the mine shaft and conveyed to a surge pile before 5 天之前 — Aggregates Equipment, Inc is a leader in manufacturing custom engineered process solutions for a range of industries Our screening equipment is used in metal processing, aggregate operations, municipal solid waste, and more Learn more about the industries we serve and the applications of our material screening equipmentScreening Equipment Applications Aggregates Equipment, 2013年4月16日 — • Trash removal: screening of grit, wood and oversize material • Grading: preparing of products with size ranges • Desliming: removal of 500 μm material With screens ranging from light duty sizing and dewatering through to heavy duty multislope screens, Linatex® vibrating screens can accommodate most minerals processing LINATEX® Vibrating Screens2020年7月27日 — #5 – Crushed stone #5 is 1 inch or smaller in size This material is perfect for road and paver base #8 – These stones are between 3/8 and 1/2 inch long It is the most common stone used for concrete mixes #10 – Crushed stone #10 is known as screenings or dust Most use this material to create pavers and concrete blocks Specialty 7 Different Crushed Stone Sizes and Their Applications ReAgg

Screening Equipment 101: Everything You Need to Know

Screening equipment is used in several industries to sift and separate matter of different sorts and sizes This mechanical material handling process allows matter to be broken down into sellable products Without these innovative machines, organizing material sizes after the crushing process would take an enormous amount of manual labor in 2023年11月22日 — A trommel screen is named for the screened cylinder used to separate materials by size, for example, separating the biodegradable fraction of mixed municipal waste or separating different sizes of mulch or crushed stone Production rates can vary from 20 to30 yardsan hour toseveral hundred yards of Trommel Screens 101 Earthsaver Equipment2017年10月1日 — This paper offers analysis of factors related to production and storage of graded crushed stone, which adversely impact the service life and wear resistance of asphaltconcrete motor road pavementsAutomation for Crushing and Screening Equipment to 2024年8月14日 — Derrick® Dry Sizing machines have been providing the industrial minerals industry solutions for fine dry screening application for over 60 years Traditional Derrick Dry Sizing machines have utilized high speed, low amplitude, vertical elliptical motion to solve countless difficult mineral sizing challengesDRY SCREENING Derrick Corporation

36.jpg)

screening equipment for sizing crushed liDXNne aquatroc

Screening: Sepro Sizing Screens Sepro Mineral Systems Sepro's line of sizing screen solutions are easily combined with other Sepro in mind, Sepro supplies durable and robust classifying screens for applications including fine aggregates, industrial minerals, coal processing and crushed stone,Screening Technologies for Recycled Glass Material 2023年9月1日 — Commonly used mesh sizes for aggregate screens for sale from aggregate screen manufacturers include: 3/8 inch commonly used for screening sand and gravel 1/2 inch commonly used for screening crushed stone 5/8 inch commonly used for screening largersized gravel 3/4 inch commonly used for screening asphalt or concrete mixHow To Size and Select a Vibrating Screen for an Aggregate 2023年6月3日 — It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as MeasurementControl for Crushing and Screening ProcessScreening: Sepro Sizing Screens Sepro Mineral Systems Sepro's line of sizing screen solutions are easily combined with other Sepro in mind, Sepro supplies durable and robust classifying screens for applications including fine aggregates, industrial minerals, coal processing and crushed stone,screening equipment for sizing crushed line Stone screening equipment for sizing crushed line stores78

.jpg)

Crushing and Screening Equipment for Concrete Recycling

2023年3月14日 — Crushing Screening Equipment A portable stone crusher, a wheelmounted crushing machine is used for processing concrete recycling Vibrating screens play a critical role in the concrete screening process by separating aggregates of different sizes and types Mobile screening plant Crushed concrete has a variety of uses and Your ultimate guide to screening equipment Learn how to select and use the best screening machines for your project’s needs with this comprehensive resource In the construction industry, screening machines are used to separate and classify materials such as sand, gravel, and crushed stone This helps create different aggregate grades Screening Equipment Guide Ultimate Resource for Optimal This equipment sifts through various materials to separate crushed products based on their size With screening equipment, you can ensure the correctsized materials make it through, enhancing your overall efficiency Combining crushing and screening gives you an efficient process for obtaining the correct materials for your project Powerful Best Practices for Crushing and Screening Equipment2019年7月27日 — The screening process is usually carried out for separating two or more materials of different shapes, particle sizes and densities []The vibrating screen has wide range of application in minerals industries for the screening of minerals, mineral ores and ore slurries []It also has applications in mining industries especially in coal mining industries []Shortcomings of Vibrating Screen and Corrective Measures:

Screening/Sizing McLanahan

The simplest form of sizing is screening, the purpose of which is to separate minerals or other materials into specific particle sizes to create various final products Screening equipment can be stationary or portable, designed for quick setup and teardown and for easy transport from site to site Screening equipment is commonly used to