Minerals Portable Mineral Mining Mill

Mineral Processing Plants: Modular VS Mobile Plants

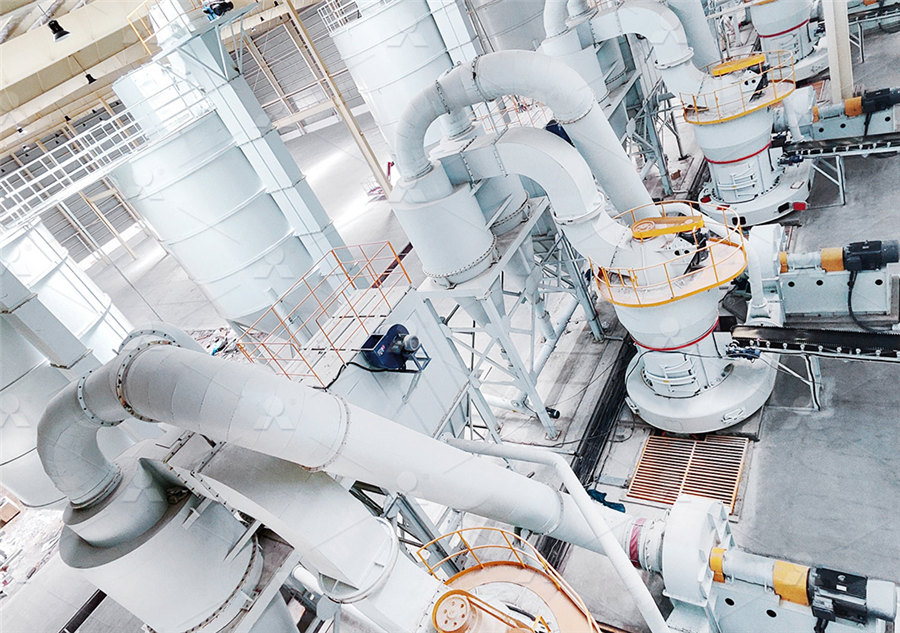

Mobile Mineral Processing Plants Designed to allow the rapid deployment of a complete plant, Sepro Mobile Mill systems are ideal for smaller tonnage operations and/or mining operations with a short mine life Easily relocatable, the main processing equipment is mounted on road transportable custombuilt trailer assembliesRME’s expanded, futureproofed, fieldupgradable RUSSELL Liner Exchange Machine range ensures fast, reliable, safe relining is even more accessible to every mine site Our industryleading technologies include Welcome to RME Fast, Reliable, Safe Mill Relining2021年9月30日 — Raymond mill adopts grinding roller and grinding ring for grinding, which is suitable for processing nonmetallic minerals with Mohs hardness below level 7, such as gypsum, limestone, calcite, talc, kaolin, Raymond Mill for Mining and Mineral ProcessingFrom mineral analysis to complete bulk weighing monitoring and sampling systems to informatics, discover the latest equipment and technology to help optimize your mining operations, and keep coal, cement, or mineral processing operations running efficiently, safely, and profitablyPortable Mining Exploration Solutions Thermo Fisher

Mining Mineral Processing Equipment

2024年9月13日 — JXSC Mine Machinery is a Mining Equipment OEM ODM from China, with over 35 years of rich experience in the mineral processing area, we provide our global customers with sustainable minerals 3 天之前 — DOVE is the world’s major manufacturer of an unmatched range of Semistationary Hard Rock mining equipment and crushing plants, for gold, platinum metals, base metals, and ferrous metals, producing high Hard Rock Mining Equipment Crushing Plants1 天前 — DOVE is the largest manufacturer of the full range of alluvial Gold Mining Equipment, Gold wash plants, Diamond mining equipment, and processing plants for Base Metals, Ferrous Metals, Light Metals Gold Mining Equipment Diamond Mining 2015年8月8日 — of mill can deliver a product with a fineness of less than 01mm Testing is required beforehand to determine the suitability of a mineral for processing in an autogenous mill Suitable minerals such as copper or iron ore Mineral processing milling

Variables affecting the fine grinding of minerals using stirred mills

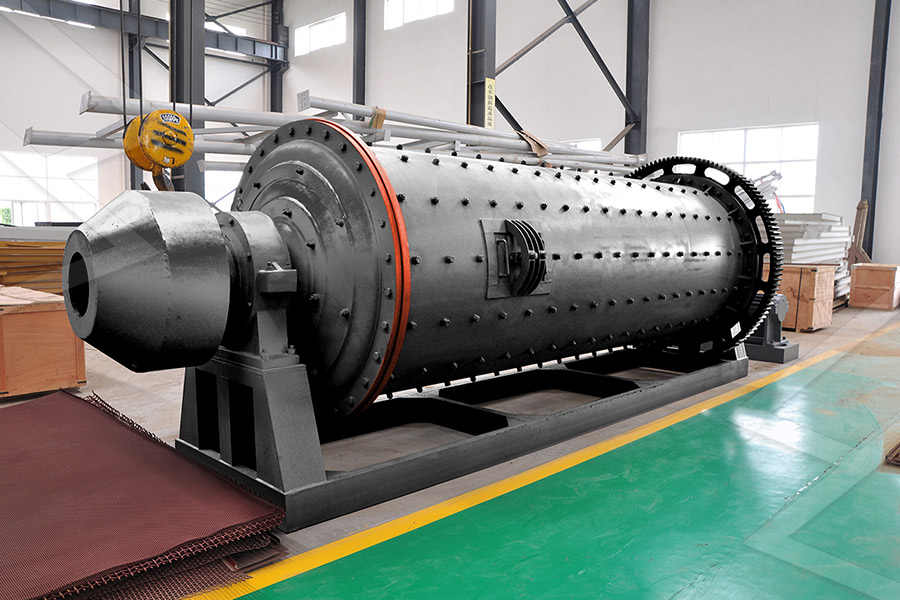

2003年4月1日 — The most commonly used stirred mills in the minerals processing industry are: Tower mill: Manufactured in Japan by Kubota It was the first low speed stirred mill applied in the minerals industry The mill operation is explained elsewhere (Stief et al, 1987; Menacho and Reyes, 1989; Jankovic, 1997, Jankovic, 1998; Jankovic et al, 1999 3 天之前 — DOVE Equipment and Machinery with over 50 years manufacturing expertise, and the largest range of mining and minerals processing technologies is the recipient of ISO 9001: 31 BALL MILLS are devices, used in mineral dressing processes and other operations (paints, pyrotechnics, ceramics, and selective laser sintering, for the grinding Hard Rock Mining Equipment Crushing Plants DOVEBy comparison IPCC is not as familiar and the downtime and mine planning issues weigh heavily with operators there is a reluctance to consider IPCC systems, and when installed, some resistance in making them work properly 52 Manufacturer Metso Metso have supplied modular and portable plants to the minerals industry since the 1970’sMobile Mineral Processing Equipment: The State of the Art 2020年8月6日 — Mines, Minerals, and “Green” Energy: A Reality Check 2 About the Author Mark P Mills is a senior fellow at the Manhattan Institute and a faculty fellow at Northwestern University’s McCormick School of Engineering and Applied Science, where he codirects an Institute on Manufacturing Science and InnovationMINES, MINERALS, AND “GREEN” ENERGY: A REALITY

.jpg)

A mill power equation for SAG mills Mining, Metallurgy

1990年2月1日 — where m p is in kW; D is internal mill diameter (meters), L is internal mill length (meters); J is total fractional charge loading of the mill; J B is the fractional mill filling by balls; ε B is the effective porosity of the charge, taken as 03; ρ s and ρ b are true densities of rock and balls (tons per cubic meter), respectively; w c is the weight fraction 2015年9月30日 — CO2 sequestration by mineral carbonation can permanently store CO2 and mitigate climate change However, the cost and reaction rate of mineral carbonation must be balanced to be viable for industrial applications In this study, it was attempted to reduce the carbonation costs by using mine waste rock as a feed stock and to enhance the reaction Ultrafine grinding and mechanical activation of mine waste 4 天之前 — EFFICIENCY: SPEEDMINER ® Mobile Fully Integrated Hard Rock plant is designed with advanced technology to ensure 100% recovery of gold and other metals production, with no loss PRODUCT RANGE: SPEEDMINER ® Mobile Hard Rock plants are produced in 13 standard models with capacity range of 2120 TPH SELFSUFFICIENT MOBILE HARD ROCK GOLD MINING EQUIPMENTOur mineral sizers are specially desinged for mining industry It is in heavy duty working manner whether it is worked in mining site open or underground for crushing the raw ore ,overburden or installed in the mineral concentration plant for reduction the size of the ore, it will be performenced in high working efficiency and low power consumptionMineral Sizers – ZJH minerals

.jpg)

Stirred media mills in the mining industry: Material

2020年6月1日 — Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional properties This review describes stirred media mill technologies and operating principles, and summarises stress intensity theory which can be used for selecting efficient 2020年6月25日 — The study, released earlier this year, showed off plans for a 26year openpit mine with “bottom quartile cash costs” and average production of circa28,000 t/y of copper and circa22,000 t/y of nickel in OZ Minerals, Loesche team up following West2022年5月16日 — How is AI Incorporated in Mining for Processing Minerals and Exploration? Sensors equipped with artificial intelligence algorithms ensure that the size of rocks entering the mill and traveling on the Using Artificial Intelligence for Mineral 3 天之前 — Types: Small portable jaw crusher with vibrating screen; Small portable jaw crusher with belt conveyor; Small portable hammer crusher; Application: The small portable rock crushers widely used to crush and screen various rocks, stone, aggregates, construction materials and ores, including limestone, granite, marble, gypsum, basalt, Small Portable Rock Crushers JXSC Machinery

.jpg)

Statutory Instrument 185 of 2021 [CAP 21:05 veritaszim

2021年6月25日 — Mining (General) (Amendment) Regulations, 2021 (No 26) IT is hereby notified that the Minister of Mines and Mining Development has, in terms of section 403 of the Mines and Minerals Act [Chapter 21:05], made the following regulations:— 1 These regulations may be cited as the Mining (General) (Amendment) Regulations, 2021 (No In a mining plant or processing mill, they have a big grinding circuit for crushing raw material, these are usually Ball or SAG mills Inside these Sag/Ball mill are big steel balls that grind ore via an impact process In simple terms, these hard metal steel balls get to the top of the rotating chamber and fall down crushing the ore being Dealing With Scat in Mill Processing PumpEng Submersible 2016年5月12日 — Each Portable Truck Mill also includes water tank, pumps, Caterpillar Diesel Electric Set, wet and dry reagent feeders where applicable and complete launders, piping and electrical wiring PORTABLE MILL 57 TON This Portable Mill was designed for use at a mine in Bolivia and utilizes a Diesel Power Plant with belt drivesSmall Mineral Processing Plant Design 911MetallurgistMineral Grinding plant,Grinding Machine,Mineral Grinding Mil Our grinding mills include VM Vertical grinding mill, MTW European grinding mill, T130X Super fin Home Productskefid minerals portable mineral mining mill

Portable Gold Wash Plant Gold Mining Equipment DOVE

3 天之前 — WIDE RANGE: DOVE Equipment Machinery is a leader and powerhouse in the mining equipment manufacturing industry, producing the largest range of Portable Gold Wash Plants (Portable Gold Processing Plants) for small, medium and large scale mining operations, with the capacity to handle material ranging as below: EXPLORER ® 5 天之前 — Small scale gold mining equipment is portable, so many people use it for small gold processing plant wet pan mill Less than 300mm feed size jaw crushers are called a small jaw crushers, also known as diesel jaw crushers Hot product PE 250×400, PE 400×600 We manufacture and sell portable mineral processing equipment, Onestop Small Scale Gold Mining Solution Equipmnet Mineral Processing2 天之前 — At Bellian Mining Machinery, we specialize in crafting advanced solutions for ore crushing, sand making, and grinding processes Whether it's efficiently crushing ores, creating highquality sand for construction, or precision grinding for various applications, Choose Bellian Mining Machinery for all your mining and processing needs, where Ore Crushing, Sand Making, Grinding Machinery Bellian Mining 2023年5月27日 — Mercury is usually added to the wet pan mill to mix with the gold particles, so the wet pan mill is often referred to as an amalgamation grinding mill Gold Ore Rock Crusher Gold ore rock crusher is mainly for crushing the hard goldbearing quartz rocks into pieces with a particle size of less than one inch to improve the grinding efficiency8 Pieces of Gold Mining Equipment to Get Gold Concentrates

History Swiss Tower Mills Minerals AG

Inspired by his creative idea that the novel and most energy efficient grinding concept for fine and ultrafine grinding of industrial calcium carbonate, as developed by Omya during the second half of the last 2023年5月1日 — Thermo Scientific portable analyzers can be used in the exploration and mining of a wide variety of base metals, precious metals, rare earth elements, mineral fuels, industrial minerals, and gasbearing strata samples Exploration Portable XRF analyzers provide fast acquisition of geochemical data for rapid delineation of ore boundaries and theThermo Scientific Portable XRF Analyzers Thermo FisherA practical guide to improving mining and mineral operations From mineral analysis to complete bulk weighing monitoring and sampling systems to informatics, discover the latest equipment and technology to help optimize your mining operations, and keep coal, cement, or mineral processing operations running efficiently, safely, and profitablyPortable Mining Exploration Solutions Thermo Fisher A review of machine learning in processing remote Moreover, we used appropriate keywords to search for the documents focused on the application of machine learning methods for delineating geological target features including lithological units, alteration types, minerals, and structures which are key elements in mineral exploration and can be Minerals Portable Mineral Mining Machine

.jpg)

Integrating mining and mineral processing for advanced mining systems

2002年1月1日 — The integration of mining and mineral processing technologies into new advanced mining systems is considered to offer several benefits, including selective mining, reduction in waste, increased Mill relining is the most specialised and important task in the maintenance of a mineral concentrator Mill relining dictates shut down times, mill availability, throughput, and therefore, mine site profitability For almost 40 years, we’ve worked with hundreds of mine sites globally to optimise their mineral processing operations Our Welcome to RME Fast, Reliable, Safe Mill ReliningMEC thanks the Mining Metallurgical Society of America (MMSA) for their generous annual contributions MMSA's support is an important component in MEC's ability to serve its mission of providing mining and minerals education for grades K Welcome Minerals Education CoalitionTech Mill Services is a mineral processing consultancy offering Due Diligence for JORC (2012) and NI 43101, plant audits, flowsheet development and process design plant audits, flowsheet development and process design We work globally with clients on greenfield and operating mining projects Tech Mill Services is a mineral processing Mineral Processing Tech Mill Services

Roll Mill Mineral Processing Plants In Myanmar Crusher Mills

process coal mining in myanmar – Grinding Mill China in mining and minerals processing having also Mining mills for sale,Mining Myanmar coal firms to set up mineral processing plants and 2020年8月24日 — Cobalt, Critical, Strategic and Rare Earth Minerals and Metals (1,392) Commodity SuperCycle and Decline (1,047) Conflict Minerals (100) Copper (1,867) Corporate Social Responsibility (313) Deep Sea Mining (158) Diamonds – Mining, LabGrown and Conflict/Blood (978) Elliot Lake (38) Emerald, Ruby, Sapphire, Gemstone Mines, Minerals, and “Green” Energy: A Reality Check – by Mark P Mills With 37 years of industry experience, JXSC has built a reputation as a leading ball mill manufacturer among ball mill manufacturers Since 1985, With over 200 successful mining projects in more than 40 countries, Ball Mills Manufacturer JXSC3 天之前 — DOVE ball mill is integrated and used in DOVE Portable and SemiStationary Hard Rock plants (Hard Rock processing plants) to efficiently grind the ore from primary deposit until the liberation size of valuable minerals is reached DOVE ball mill is the key grinding equipment after material is crushedBall Mill Ball Mills Wet Dry Grinding DOVE

.jpg)

List of Mining Minerals Sector Stocks with Industry Ticker

Ticker > Sector > Mining Minerals Mining Minerals The one that extracts minerals from mines Get the latest information about companies present in Mining Minerals sector Today's Gainer / Loser Gainer; Loser; Company price Rs Change % RAW Edge Industrial: 4338 +403%: 20 Microns: 31055 +328%: MOIL: 40370 +224% 3 天之前 — Bruker’s portable and handheld XRF for minerals allows you to perform onsite real time element analysis of mineralogical and geological samples CTX and TRACER 5 Handheld XRF Analyzers are a fast and accurate tool for all aspects of mining, and are sometimes also referred to as portable mineral analyzers or handheld mineral analyzers Portable Element Analyzers for Minerals BrukerThe Global Marine Mineral Resources project studies deep ocean minerals that occur within the US Exclusive Economic Zone and areas beyond national jurisdictions such as critical minerals, from mine tailings We plan to analyze the existing data and reports from an active mine site on the composition of their mill tailings pile, and Minerals 101 US Geological Survey USGSgov5 天之前 — JXSC has more than 38+ years of experience in manufacturing mineral gravity separation equipment Mainly includs jig separators (mineral jig concentrator), mobile jig concentrator plants, Gemini shaker tables, shaking tables (gravimetric tables, gold shaker table), spiral chutes (spiral separators), and centrifugal concentratorsIt is very suitable Gravity Separation Equipment JXSC Machinery

.jpg)

Portable NIR: An Alternative to Mineral Analysis Laboratories

2024年3月31日 — Introducing Portable NIR Mineral analysis laboratories have long played a critical role in the mining exploration process It also analyses the intensity of the reflected light to determine the concentration of key minerals Within the mining exploration context, NIR is the best choice when speed and quantity are the priority 2003年4月1日 — Svedala detritor: ECC International developed its first mill in the 1960s and currently around 200 mills operate in kaolin and calcium carbonate processing plants (Lofthouse and Johns, 1999)The first installation in Australia was at the Elura lead/zinc mine where two mills are in operation Another 18 ECC mills were installed at Century zinc Variables affecting the fine grinding of minerals using stirred mills 1 天前 — DOVE is the largest manufacturer of the full range of alluvial Gold Mining Equipment, Gold wash plants, Diamond mining equipment, and processing plants for Base Metals, Ferrous Metals, Light Metals Gold Mining Equipment Diamond Mining 2015年8月8日 — of mill can deliver a product with a fineness of less than 01mm Testing is required beforehand to determine the suitability of a mineral for processing in an autogenous mill Suitable minerals such as copper or iron ore Mineral processing milling

Variables affecting the fine grinding of minerals using stirred mills

2003年4月1日 — The most commonly used stirred mills in the minerals processing industry are: Tower mill: Manufactured in Japan by Kubota It was the first low speed stirred mill applied in the minerals industry The mill operation is explained elsewhere (Stief et al, 1987; Menacho and Reyes, 1989; Jankovic, 1997, Jankovic, 1998; Jankovic et al, 1999 3 天之前 — DOVE Equipment and Machinery with over 50 years manufacturing expertise, and the largest range of mining and minerals processing technologies is the recipient of ISO 9001: 31 BALL MILLS are devices, used in mineral dressing processes and other operations (paints, pyrotechnics, ceramics, and selective laser sintering, for the grinding Hard Rock Mining Equipment Crushing Plants DOVEBy comparison IPCC is not as familiar and the downtime and mine planning issues weigh heavily with operators there is a reluctance to consider IPCC systems, and when installed, some resistance in making them work properly 52 Manufacturer Metso Metso have supplied modular and portable plants to the minerals industry since the 1970’sMobile Mineral Processing Equipment: The State of the Art 2020年8月6日 — Mines, Minerals, and “Green” Energy: A Reality Check 2 About the Author Mark P Mills is a senior fellow at the Manhattan Institute and a faculty fellow at Northwestern University’s McCormick School of Engineering and Applied Science, where he codirects an Institute on Manufacturing Science and InnovationMINES, MINERALS, AND “GREEN” ENERGY: A REALITY

A mill power equation for SAG mills Mining, Metallurgy

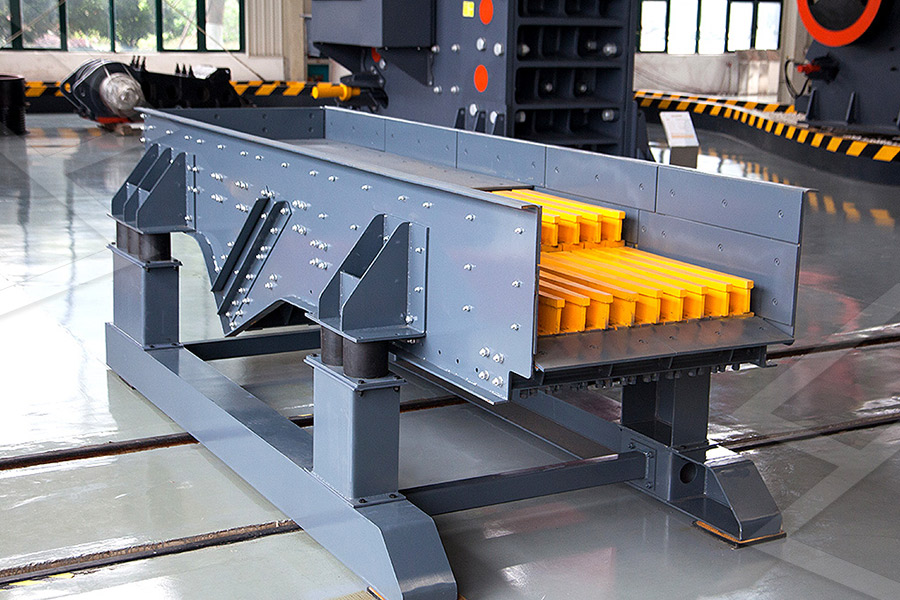

1990年2月1日 — where m p is in kW; D is internal mill diameter (meters), L is internal mill length (meters); J is total fractional charge loading of the mill; J B is the fractional mill filling by balls; ε B is the effective porosity of the charge, taken as 03; ρ s and ρ b are true densities of rock and balls (tons per cubic meter), respectively; w c is the weight fraction 2015年9月30日 — CO2 sequestration by mineral carbonation can permanently store CO2 and mitigate climate change However, the cost and reaction rate of mineral carbonation must be balanced to be viable for industrial applications In this study, it was attempted to reduce the carbonation costs by using mine waste rock as a feed stock and to enhance the reaction Ultrafine grinding and mechanical activation of mine waste 4 天之前 — EFFICIENCY: SPEEDMINER ® Mobile Fully Integrated Hard Rock plant is designed with advanced technology to ensure 100% recovery of gold and other metals production, with no loss PRODUCT RANGE: SPEEDMINER ® Mobile Hard Rock plants are produced in 13 standard models with capacity range of 2120 TPH SELFSUFFICIENT MOBILE HARD ROCK GOLD MINING EQUIPMENTOur mineral sizers are specially desinged for mining industry It is in heavy duty working manner whether it is worked in mining site open or underground for crushing the raw ore ,overburden or installed in the mineral concentration plant for reduction the size of the ore, it will be performenced in high working efficiency and low power consumptionMineral Sizers – ZJH minerals